Synthetic Felt vs. Asphalt Felt

What is roofing underlayement?

Roofing underlayment is what lies between the shingles and the roof sheathing, or roof deck, which is typically either plywood or OSB. It’s installed directly on the roof deck and provides a secondary layer of protection from the elements, including rain, snow, and wind.

Types of Roofing Underlayment

There are two main types of roofing underlayment:

Felt

Synthetic

Each product has its pros and cons, and the type you choose may depend on your geographical area, roofing materials used, roof design, budget and what your roofing contractor may suggest.

Felt Roofing Underlayment

Felt roofing underlayment is one of the oldest types of roofing underlayment. It’s created by saturating paper or fiberglass mat with asphalt.

Felt roofing underlayment is typically available in two types: No.15 felt and No. 30 felt. Compared to No. 15 felt, No. 30 felt is typically thicker, stronger, and may be less prone to tearing or ripping off during installation or weather events.

Pros:

The main advantage of using felt roofing underlayment is cost. Felt underlayment tends to cost less compared to synthetic underlayment, which is why it’s often the go-to for budget-conscious homeowners.

Cons:

There are several disadvantages to using felt underlayment on a roof. One disadvantage of traditional felt roofing underlayment is it generally can’t be left exposed for more than a few hours. The material may dry out or leach oils in the heat. This would impact the felt’s ability to protect against moisture.

Other drawbacks of felt underlayment include:

Prone to tearing in high winds and during the strain of installation.

If exposed to moisture, the mat can absorb water and wrinkle the felt, making it harder for the shingles to lay flat. Therefore, shingles should be installed immediately after felt roofing underlayment is installed if possible to ensure optimal protection.

Felt underlayment also weighs more, which can make it harder for roofing contractors to drag rolls of it up a ladder and onto a roof.

It also has a slippery surface, which can sometimes make it more difficult to install.

The weight also leads to less material per roll. This means more potential seams instead of a single course with no laps.

Felt Roofing Underlayment and Warranties

If felt underlayment is installed it may also prevent you from being protected under the manufacturer’s warranty, which may require synthetic underlayment.

Synthetic Roofing Underlayment

For enhanced water-resistance and protection from the elements, many roofers are choosing to go the route of synthetic roofing underlayment. These products are usually made from long-lasting polymers, which provide added strength and longevity. This type of underlayment is typically moisture-resistant, and when it’s installed correctly, it offers better protection from the weather compared to felt.

Synthetic roofing underlayment materials are not standardized, so different manufacturers may make their products differently, and therefore may have different levels of performance. Be sure to do your research and talk with a trusted contractor who can help guide you in selecting the right roofing materials to protect your home.

Pros:

There are four main advantages to installing synthetic roof underlayment rather than felt. Compared to felt, synthetic roofing underlayment is:

• Tough

• Fast to install

• Safe

• Repels water

• Synthetic underlayment has a tough and durable construction with an extremely high tear strength compared to felt.

• Synthetic roof underlayment is extremely durable. It typically doesn’t tear and is suitable for extended UV and moisture exposure in some cases, which is especially helpful if there’s a bit of lead time before your roof covering is installed.

Synthetic underlayment also stands up to boot traffic, which is important when your roofing contractor is walking around on its surface as it’s being installed. At Owens Corning Roofing, we call this “use after abuse” — the product can still perform as designed even after the abuse it takes during installation.

Synthetic roofing underlayment also tends to be:

Lighter* – Up to four times lighter in some cases

Fast to install – Because there is more material per roll compared to felt (synthetic roofing underlayment comes in wider and longer rolls), it results in fewer trips up the ladder for your roofers, saving them time and perhaps helping the job move along faster. For instance, a typical 2700 square-foot home might require three rolls of synthetic underlayment compared to 14 rolls of No.30 felt to cover the same area.

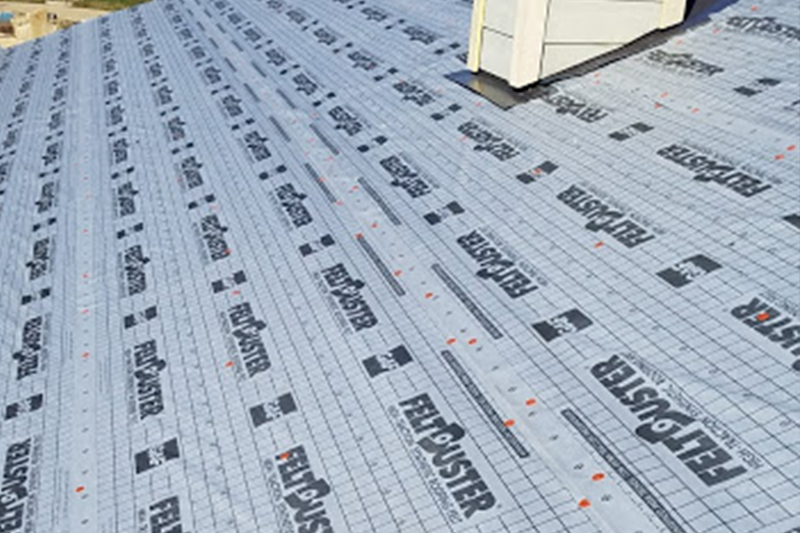

Safe – Synthetic underlayment is also advantageous for worker safety — the surface of many synthetic roofing underlayments, including those offered by Owens Corning, features a variety of slip-resistant surfaces for enhanced walkability. It’s also usually well-marked with overlap guides and indicators of where fasteners should be placed, helping to improve consistency and accuracy during installation.

Moisture-resistant – Where felt products tend to absorb water, synthetic roofing underlayments are built to repel water. This is important for homeowners concerned about moisture infiltration, especially if they plan to leave the underlayment exposed for a prolonged period of time.

Because it’s made of plastic, synthetic underlayment is typically resistant to mold growth, a definite advantage over felt.

Cons:

Many synthetics are competitively priced, but when compared to felt, the main drawback of synthetic roofing underlayment is the cost. The upfront investment in higher quality roofing materials, however, could save you money down the road. You can’t put a price on the peace of mind knowing that your roof is sufficiently protected from moisture.